Here’s another tire rim stove project you might want to do for your backyard cooking!

It’s a simple stove made out of four tire rims with steel tube legs. Compared to other DIY tire rim outdoor cookers this stove is more comfortable to use for its height. And because this DIY stove consists of more tire rims, it has slightly more room in the firebox.

This tire rim stove also has a small baffle on top of it. This allows you to use a frying pan without the handle melting from the heat escaping from the holes.

Do you like this DIY stove idea? Get yourself some old tire rims now and follow the step-by-step tutorial below!

Click on any image to start the lightbox display. Use your Esc key to close the lightbox. ?

Building a Tire Rim Stove

Materials

- 4 Old Tire Rims

- 3 6″ long pieces of 1 1/2 EMT Tubing

- Scrap Metal Sheet

- Piano Hinge

Tools

- Permanent Marker

- Welding Machine

- Plasma Cutter

- Chisel

- Hammer

- Angle Grinder

- Belt Sander

- Bandsaw

- Wire Brush

Instructions

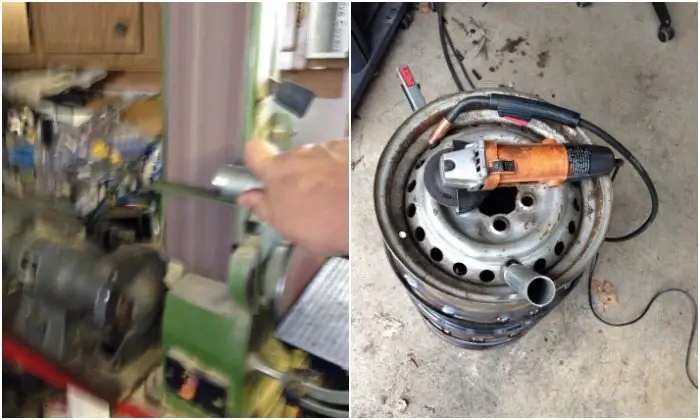

Collecting the rims: You need cheap steel rims. Nothing fancy here. I had 2 old 14″ Volvo rims lying around but I needed 2 more so I turned to Craigslist and found 2 15″ BMW rims cheap, only $25. This worked out pretty well since they would interlock when stacked.

I grabbed a plasma cutter and removed the center section from one of the 14″ rims. You could use a sawzall or cutoff wheel too.

I stacked the rims to get an idea of how tall it would be. Even with 4 rims, it seemed a little short but I will add legs later to fix that.

Cleaning everything up: These had the old fashion lead wheel weights. A chisel and hammer removed these pretty quickly. A knife could be used to remove the valve stems but since I had the chisel in my hand, I used it to chop them off too.

After that, I ground the inside of the 15″ rims and the outside of the 14″ rims so I could weld them together.

Welding it together: I used little 1-inch stitch welds every 4 inches crisscrossing my way around the rims. I started with the top section but anyway you feel comfortable works. Just remember to stack them properly.

I started with a 14″ on the bottom and alternating on the way up to a 15″ on top. The two bottom rims face down while the two top rims face up giving a large firebox.

You should see good penetration on the opposite side of the rim. I didn’t completely weld the circumference. You can if you want to.

Legs: I needed a little more height. I decided to make a door on the side rather than just a bare opening so the extra height will provide good airflow.

I used a piece of 1 1/2 EMT tubing and cut a couple of ~6-inch pieces. I didn’t measure, I just cut off what looked proportionately appropriate and made three of the same length.

A little prep on the belt sander to remove the galvanizing and they’re ready to weld on.

Valve stem holes: I was going to weld up the valve stem holes but then I looked through the top and noticed the valve stem hole in the second rim down was in a nice position to hold a thermocouple. It’s partially shrouded from the rising fire and about the right size so I left them alone.

Cutting the fire door: I took the Plasma cutter and made a vertical cut up the edge of the middle weld between rims. Then I switched to a sawzall to cross the middle cutting right through a stitch weld. I then went back to the plasma cutter and finished the cutout using the sawzall to cross the middle on the way down.

Continued Page 2…