Roof Eyelets and Hooks:

The hooks are actually an option, but something I find makes it easier to assemble the finished roof.

At each of the 16 points around the roof edge where the timber/s point to (ie equidistant), you should put a brass “push-through” eyelet which is large enough to lace your cord through.

Every second of these should have an “S-hook” fitted so that you can easily hook tie-down rope through it when you are assembling the yurt. I custom-made mine out of large galvanized nails, bent into a funny U shape, such that the head of the nail will not fit through the brass eyelet in the tent, but the shank will.

Bending them like this, I can permanently fit them to the roof, and not lose them, but can still lace the rope around the open end easily.

Pins for connecting walls to roof:

Look closely at the last picture in this set, and you’ll see that the vertical part of the “pin” appears to join onto the nut/bolt that goes through the wall lattice X. It’s actually all the same bolt, just a long one, with the head cut off. The bolt is a 1/4″(6mm) diameter, 120mm long bolt with thread on about 1inch of the shank.

CANVAS COMPONENTS

Wall:

My yurts are constructed such that when all the timber frames are together, and the roof timbers are fitted, the top edge of the wall/lattice has a roof timber fitted on every second X joint. This leaves every second bolted joint free, and accessible for hanging the wall from.

To do this, I sew a reinforcing to the canvas just below the point that would be matched onto the joint in the wall, and sew a wooden “toggle”, via a strong nylon cord into the reinforcing. The wall canvas can then just be hitched-up onto the wall timbers, and hung there from the wooden toggles.

This gives a result that is invisible from the outside of the tent, easy to erect in a repeatable way, and still within the spirit of the construction.

These tension ropes/cords that you can (barely) see going around the wall (I use two bands, each of 3mm woven venetian blind cord) must be permanently fitted to the timber walls before the canvas walls and roof are put on. I will go into how these cords are tied to the wall at the end. During test assembly though, you can just wrapt them round the whole yurt, and at least the top one must be partially tightened, or the timber lattice walls will fall down. This must be done before any weight is put on them like when you put the the roof timbers us, or the wall canvas is put on.

Roof:

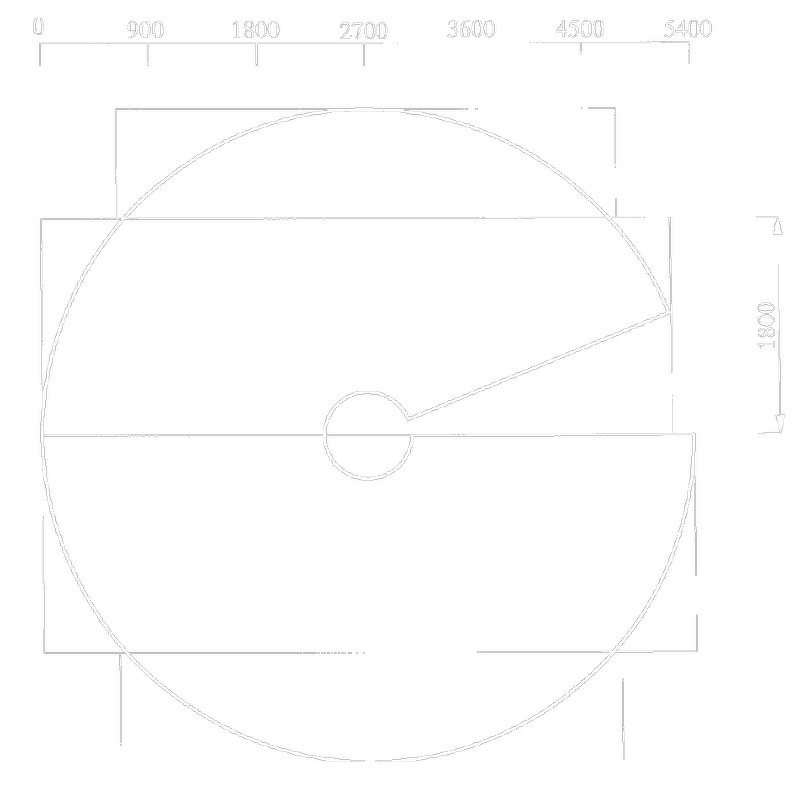

Buy 16 metres of roof canvas at approx 6′ wide, and cut/sew it as per the picture below.

Notice how there are two sections 1800 (6′) wide, these are the full width of the canvas. The two smaller rectangles (top and bottom) are from the same length of canvas, just split down the middle to half their width.

The “wedge” that is shown missing needs to be cut out and sewn up so that the roof canvas becomes “cone” shaped. to match your roof pitch.

I sew a flat and straight “band” of canvas, about 20cm (6″) wide, all the way around the roof edge. This fabric is deliberately NOT curved to match the roof, it is instead straight to match the walls, and it hangs from the bottom of the roof, down the walls, and fully covers-over the wall->roof joint making is really wind/rain/sleet/bug/insect proof.

Don’t throw out that “wedge” that you cut out from the yurt…. Cut the biggest equilateral triangle or circle that you can from it, and use that as the “cap” to go over your vent hole. You’ll need at least 24′ (8m) of cord/rope to hold that ‘cap’ in place (three ropes that go from the tips of the triangle or edge of the circle out to the walls to be tied off.)

Continued Page 5…