Looking for a unique gift? Then this DIY knife block should do the trick!

This project is not for the average DIYer as it requires access to a CNC machine to cut the pattern in the ply. If you have a very good hand and an equally good jigsaw you should have no difficulty either. The last option would be a good, old-fashioned fret saw but we’re guessing there are not too many of those in your tool kit :)

Once cut, there’s a bit of manual work involved such as bevelling the edges, gluing, and sanding, but it shouldn’t take a lot of time if you have the right tools. And of course, if you are getting this done on a CNC machine, you might as well get a few done so that you’ve got those Chrissie gifts well and truly covered!

If you don’t have access to a CNC machine and question your jigsaw skills, use this tutorial as an inspiration for your own, simpler design. You don’t need to have a workshop full of high-tech gear all it takes is a bit of creativity and resourcefulness.

Click on any image to start the lightbox display. Use your Esc key to close the lightbox. 8-)

Materials:

- Beech Plywood:

- 700 x 290 x 15mm

- 460 x 340 x 15mm

- 350 x 340 x 15mm

- 260 x 340 x 15mm

- Magnet Ø25 x 5mm (NdFeB)

- 6mm Dowels

- Wood Glue

- Clear Varnish

- 3x Felt Pads

- Kitchen Knives

Tools:

- End mill (3mm)

- Corner Rounding Bit

- Sandpaper

- CNC Mill

- Manual Router

- Estlcam or another CAM Software

- 2D CAD Program – for customizing knife slots

Project File:

Here are some pointers when making your own knife block:

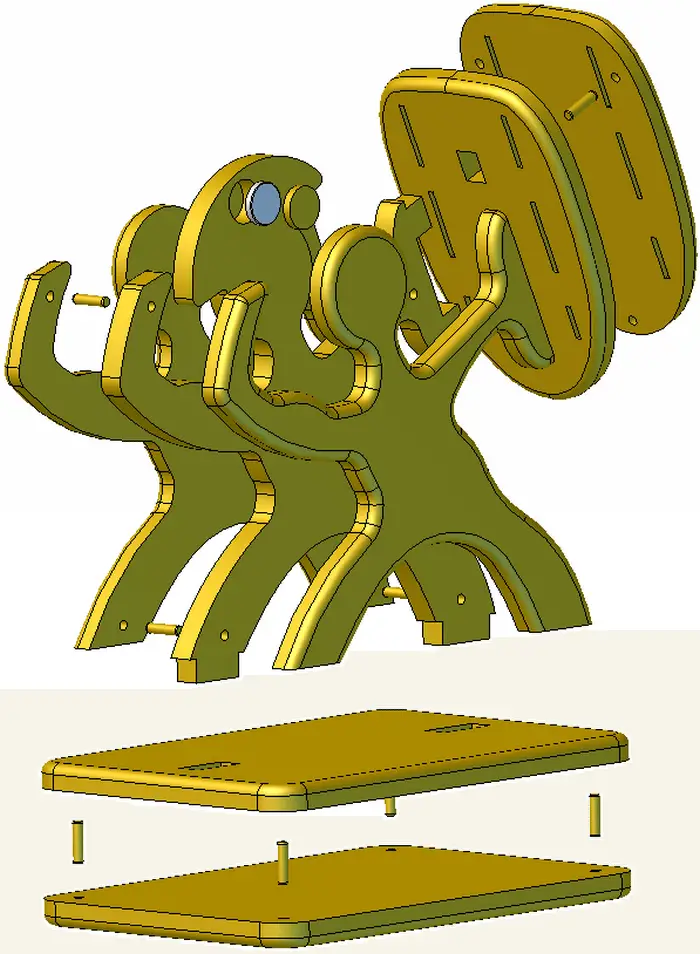

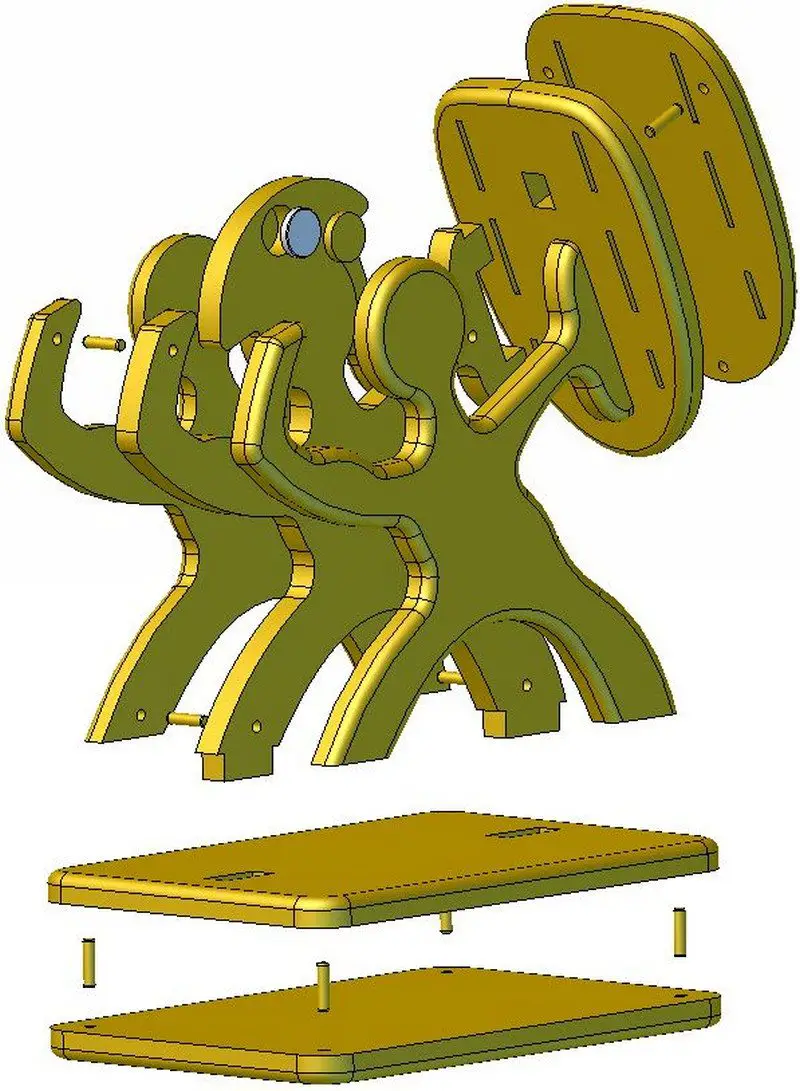

- The three main parts of this knife block consist of 15mm boards that are fit with 6mm dowels and glued together, because this process is much simpler with the machine than creating thick solid parts.

- If your wood board has a different thickness as the one mentioned here (15mm), you must adjust the drawings accordingly to make sure the parts will fit perfectly.

- Don’t forget to adjust the size of the knife slots according to the knives that you have. Use 2D CAD software for this.

Isn’t it a great project to try?

Thanks, Christian Knuell for this amazing project!