Cut the tops off below the rims.

This is the assembled garden structure on top of the drums, seen from two slightly different angles.

Adjust the structure’s balance and support its joints with wooden boards. You could tilt the structure slightly toward the drainpipe to improve the water flow.

Cut strips of burlap (or another material), fasten them to the tops of the vertical pipes and drape them down the inside of the pipes. This gives the plant roots something to latch onto.

Next, cut and assemble the tubing so that you can pump water from one barrel up to each of the four vertical pipes. You could also pump water from the barrel that receives drainage to the barrel that feeds the system.

Scaling up for bigger, fancier systems:

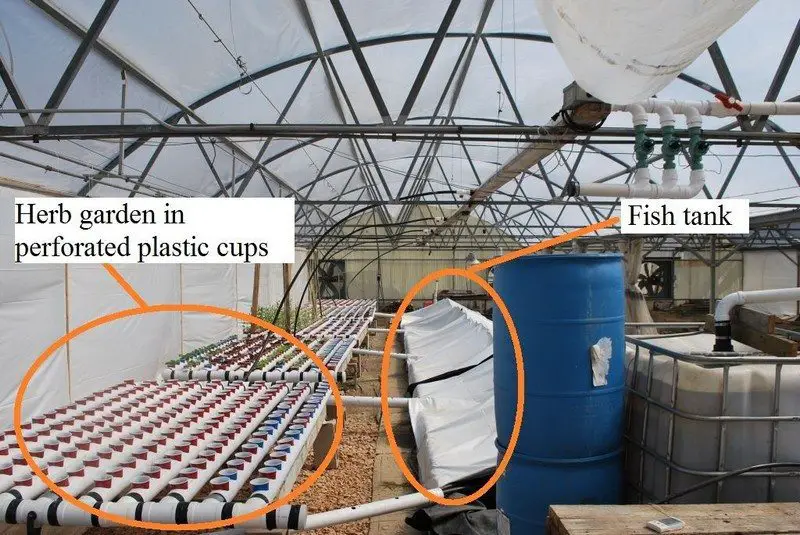

These systems can scale up to commercial size, like this greenhouse at the Center for Sustainable Aquaponics.

This arrangement shows some of the creativity and beauty possible with an aquaponic system.

There is a rocky waterfall into the fish tank and a drip-irrigation system watering soil-free plants in a rock bed.

Sean Brady shows what these systems can produce. He’s holding a trout here.

Thanks to

Contents [show]

Cost Analysis for PVC Aquaponic Systems

Combining aquaculture with hydroponics in one effective unit, building a PVC aquaponic system offers a sustainable approach to grow your own food. Anyone wishing to make investments in this creative farming technique must first understand the cost elements involved. The costs of installing and running a PVC aquaponic system are broken out here in great detail.

Initial Setup Costs

Usually, the first configuration of a PVC aquaponic system calls for some upfront material and equipment cost expenditure. PVC pipes, a water pump, an air pump, and fish tanks or containers comprise the main elements.

The overall cost for these items will vary depending on the size of your system from $200 for a small-scale system to over $1,000 for a bigger, more intricate configuration. Usually the most reasonably priced components of the system, PVC pipes and connections appeal to builders on a budget.

Ongoing Operating Expenses

Once your PVC aquaponic system is operational, there are continuing expenses to consider. Fish food, pump energy, and sporadic replacement of components like tubing or the pumps themselves fall among them. Monthly costs could vary from $20 to $100 depending on the kind of fish and plants you decide upon. Your budget should be planned with consideration for these ongoing expenses.

Potential Savings

The possibility for major grocery savings is one of the most enticing features of a PVC aquaponic system. Your food costs will be much lower if you raise fish and grow your own vegetables. Furthermore, PVC aquaponic systems require less water than conventional soil-based plants, which would help you save money on your water bill—especially in areas where water is a luxury.

DIY vs. Professional Installation

For those less inclined toward do-it-yourself projects, professional installation can be a choice even if many enthusiasts choose to build their PVC aquaponic systems from start. By doing it yourself, you might save a lot of money—possibly decreasing expenses by up to 50% compared to hiring a professional. For those not familiar with the equipment or methods needed, though, a professional installer can guarantee proper and effective setup of your system.

Long-Term Investment and ROI

Purchasing a PVC aquaponic system is an investment in sustainable living as well as a reasonably cheap method of farming. Growing your own produce increases personal happiness and has an environmental impact in addition to saving money on food, therefore measuring the return on investment in these respects.

A PVC aquaponic system can last many years with appropriate maintenance, producing fresh food and fish with low input relative to conventional agricultural techniques.

Understanding the financial side of PVC aquaponic systems can help you to properly plan and take use of home-grown food without going broke.

Enhancing PVC Aquaponic Systems with Advanced Modifications and Automation

Technological developments allow automation to improve the efficiency and simplicity of maintenance in PVC aquaponic systems. This part looks at several approaches to including automated technologies and sophisticated changes in your system, optimizing processes and raising output.

Automated Water Quality Management

Water quality is one of the major elements in preserving a healthy PVC aquaponic system. Advanced sensors can track pH, temperature, ammonia levels, and other important water quality criteria nonstop. Real-time changes and alarms made possible by automating this procedure with digital controls help to keep the ideal conditions for plants and fish. This guarantees that your system runs without much interaction, therefore lowering the requirement for hand testing and changes.

Automated Feeding Systems

The health of the fish in a PVC aquaponic system depends on regular, correct feeding. Not only save time but also maximize feed utilization and lower waste by automated feeders dispensing the correct amount of food at set times. As your system expands, these methods can be customized depending on the type and size of fish, therefore facilitating management of feeding patterns.

Energy Efficiency Upgrades

Any PVC aquaponic system, especially when scaled up to a commercial capacity, gives great weight on energy usage. Using solar-powered solutions and energy-efficient pumps will help to greatly cut power use. Including battery backups also guarantees that the system keeps running during blackouts, therefore safeguarding your aquatic and plant life from possible damage resulting from system faults.

Remote Monitoring and Control

IoT (Internet of Things) technologies allow PVC aquaponic systems to be remotely watched over and managed. Through your smartphone or computer, this feature lets you change settings, monitor system status, and get alerts about system performance. This degree of connectivity not only makes life easier but also improves your capacity to react fast to any problems that could develop, thereby perhaps rescuing your cattle and crops from unfavorable conditions.

Scalability and Modular Upgrades

PVC aquaponic systems are naturally modular, which allows those wishing to grow relative simplicity in scaling. Advanced expansion planning can incorporate scalable pump systems that allow higher water flow when more modules are installed and automated valves. This scalability guarantees that your system can expand with your demands without calling for a total redesign.

Including these cutting-edge changes and automation tools into your PVC aquaponic system will turn a simple arrangement into a low-maintenance, highly functional operation. Using technology will help you to guarantee a more strong and dependable food production system and increase output.

Automation and Advanced Modifications

Enhancing your vertical aquaponics DIY setup with advanced modifications can elevate the functionality and ease of use. Leveraging technology and thoughtful design can turn a basic system into a high-efficiency, low-maintenance operation. Here, we explore the top automation tools and advanced changes to optimize your vertical aquaponics DIY system.

Automated Water Quality Management

Maintaining water quality is crucial for the health of your fish and plants. Advanced sensors can monitor critical water parameters like pH levels, temperature, and ammonia content in real-time. By integrating these sensors into your vertical aquaponics DIY system, you can set up automatic alerts and adjustments. This reduces the need for frequent manual testing and ensures that your system stays within ideal conditions, enhancing both plant growth and fish health.

Automated Feeding Systems

For fish health in your vertical aquaponics DIY system, feed often and precisely. Automated feeders feed fish at the proper time without overfeeding or waste. These systems may be adjusted for fish size and kind, making maintenance easier as your aquaponics system grows.

Energy Efficiency Upgrades

More energy efficiency is needed as vertical aquaponics DIY systems expand. Upgrades to energy-efficient water and air pumps reduce power usage. Solar electricity saves money and promotes sustainability. When power goes out, battery backups keep your system running, saving your fish and plants.

Remote Monitoring and Control

The integration of IoT (Internet of Things) technology allows you to manage and monitor your vertical aquaponics DIY system remotely. Using a smartphone or computer, you can adjust settings, track the system’s status, and receive alerts on performance. This connectivity not only makes maintenance easier but also enables quick responses to any issues, which can be critical for preserving your aquaponics ecosystem.

Scalability and Modular Upgrades

One of the benefits of a vertical aquaponics DIY setup is its modular nature, which allows for easy expansion. Planning for scalability can involve installing modular pumps that handle increased water flow as new sections are added. Using automated valves and scalable designs ensures your system grows smoothly without requiring significant structural changes. This approach maximizes efficiency and simplifies future upgrades.

Incorporating these automation tools and advanced modifications can transform your vertical aquaponics DIY system into a modern, efficient, and highly productive food production unit. From automated water quality management to remote monitoring and energy-efficient solutions, these enhancements streamline operation and support long-term sustainability. With these upgrades, your vertical aquaponics DIY setup becomes not only easier to maintain but also more resilient and effective.

Conclusion

Using the synergy between fish and plants to generate high yields, PVC aquaponic systems present a sustainable and effective way for producing food in limited areas. Compared to conventional gardening, these systems are reasonably cheap and greatly less water and chemical fertilizer are needed. Integrating automation as technology develops will help PVC aquaponic systems to be more easily maintained and productive.

For more gardening projects, check out our garden cloche guide!