Are my pallets safe to Use?

Every time we run a post showing a new use for pallets, we get lots of comments about pallets not being safe to use. Never has an industry suffered from so many myths. Yes, there are pallets treated with methyl bromide, but in most countries, these are now hard to find.

Specifically, pallets treated with methyl bromide are banned in Australia, New Zealand, Europe and Canada (and probably many other countries). Methyl bromide is banned because it is a dangerous chemical – dangerous to both people and the environment. Work health and safety regulations in the above countries preclude the handling of pallets treated with this poison. Instead, pallets are either heat treated, or untreated.

So let’s start with a basic premise… every pallet is safe to use BUT it depends on what you intend to use it for! Various pyrethrins and the fungicide, propiconazole are common treatments for timber pallets. It’s also possible that harmful materials or chemicals may have been spilled on the pallet timber and been absorbed by it during use. Is that bad? Well, not if you intend to use the pallet as a fence and grow flowers in it. Vegetables, on the other hand, may be a concern.

[adinserter block=”11″]

Click on any image to start lightbox display. Use your Esc key to close the lightbox.![]()

OK – so how do you know which is which.

If the pallet has been made for export, it will, in almost all cases, be heat treated. Heat treatment (56°C for softwood and 60°C for hardwood) is effective at killing any pests that may have taken up residence in the timber. Note again that there is always the possibility that something toxic has been spilt on a pallet. For this reason, it makes sense to know what the pallet has carried or, at least, where the pallet has come from.

There are two types of pallets – one time use and multiple use. One time use pallets are typically made of cheap softwood while multiple use pallets are usually made from hardwood, or increasingly, from plastics and composites. Examples of one-time use pallets are those used by furniture manufacturers, white good manufacturers and board manufacturers. Examples of multiple use pallets are of those used by brick or paver manufacturers and heavy industry. These pallets are easy to recognise as they have coloured edges. They are also usually branded as being the property of the “XYZ Ltd”.

How do I know my pallet has not been treated with methyl bromide?

There are 500 million pallets made in the USA alone each year! How many would China make? Or Europe? Obviously, some of these pallets will not be safe to use – perhaps many. But that leaves vast numbers that are safe to use in your projects. So how do you tell the difference? If you haven’t realised it yet, I’m about to share a secret with you… we live in a global economy.

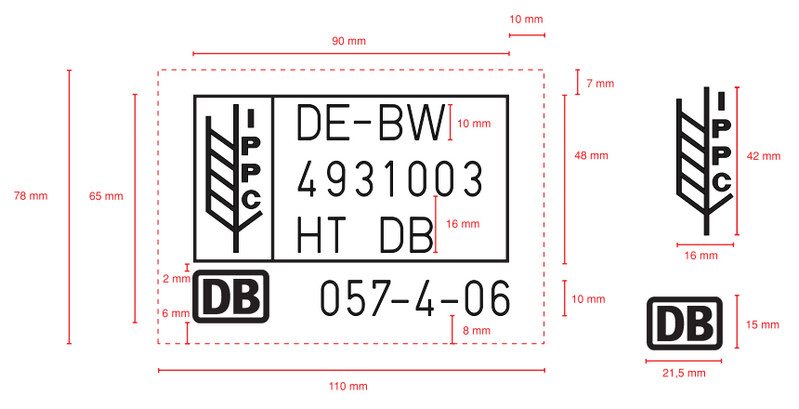

This means that any company or business wishing to transact internationally, needs to comply with international standards. One of those standards is established by the International Plant Protection Commission. The IPPC has been established to help prevent the spread of insects, fungus and mould between countries and especially, continents. Pallets used for international trade must bear IPPC certification that will contain information as shown here:

This symbol will include:

- A two letter ISO country code. For instance, AU for Australia or US for the United States.

- The 000 portion of the symbol represents the unique certification number issued to the treatment provider or wood packaging manufacturer. Inclusion of this certification number ensures that the wood packaging material can be traced back to the treatment provider or manufacturer.

- YY is the treatment abbreviation.

- HT is the code for heat treatment to a minimum of 56 degrees Celsius for a minimum of 30 minutes.

- MB is the code for methyl bromide fumigation.

What you are interested in is the two letters at the bottom right of the IPPC logo – in this example currently showing HT for Heat Treated. If the letters are MB, it means that pallet has been treated with methyl bromide. Leave it where it is. Assuming the letters are HT, you are good to go!

What if there are no markings on the pallet?

In this case, it means that the pallet has been manufactured for domestic use only. Accordingly, it does not need to be treated – by either heat or chemicals. These pallets are made from the cheapest possible timbers as they are designed to be discarded with the packaging of whatever was sitting on it. This means that you can use unmarked pallets with a high level of confidence.

I hope that this has helped to clear the air and dispel some of the myths surrounding the re-purposing of pallets. I repeat that I am not an expert on pallets. However, as someone keen to recycle and re-purpose wherever possible, I have taken the time to research and read available materials on pallet construction and treatment. I recommend that you reassure yourself by doing some research to determine what may or may not be safe in your locale.

How to dismantle a pallet

Let’s face it, pallets are not meant to come apart. They are manufactured with galvanised nails that have serrations to bind to the wood. Nonetheless, pallets can be dismantled if reasonable care is taken. Because pallets are made from very inexpensive (read cheap) timber, you are guaranteed to get splinters handling pallets if you do not wear gloves. The following instructions are courtesy of the Canadian Pallet and Container Association.

How to > disassemblyofpallets

It seems that there are as many ideas for re-purposing pallets as there are people on the face of the earth. We would love to see your project when it’s finished. Even better, take lots of photographs and write a guest blog for us.

If you have any questions or suggestions, just use the comment option below. Thanks for joining us.

The OBN Team