The R-value stands as a pivotal term in the quest for energy-efficient buildings. This article unravels the concept of this value or thermal resistance, a measure critical to effective insulation. We delve into its significance, how it’s measured, and its impact on energy savings.

This article aims to empower homeowners and builders with knowledge, ensuring informed decisions for optimal thermal comfort.

Contents

- 1 What is R-Value in Home Insulation?

- 2 Measuring R-Value

- 3 R-Value in Different Materials

- 4 R-Value and Building Regulations

- 5 Improving Home Energy Efficiency with R-Value

- 5.1 Assessing Current Insulation

- 5.2 Upgrading Insulation

- 5.3 Addressing Air Leaks

- 5.4 Insulation and Ventilation Balance

- 5.5 Energy-Efficient Windows and Doors

- 5.6 Tailoring Insulation to Climate

- 5.7 Innovative Insulation Technologies

- 5.8 Regular Maintenance and Inspections

- 5.9 Impact on Energy Costs and Environmental Footprint

- 6 FAQ on R-Value Home Insulation

- 6.1 Can R-value degrade over time, and how can it be maintained?

- 6.2 Are there any health concerns associated with insulation materials?

- 6.3 How does insulation contribute to soundproofing?

- 6.4 Can insulation improve indoor air quality?

- 6.5 Are there insulation options for homes in extremely humid climates?

- 6.6 How does the R-value requirement differ for commercial and residential homes?

- 6.7 What are the cost implications of choosing high R-value insulation?

- 6.8 Is it possible to have too much insulation in a home?

- 6.9 How does insulation contribute to a building’s fire safety?

- 6.10 Can insulation be recycled or reused?

- 7 Conclusion

What is R-Value in Home Insulation?

Every homeowner is mindful of the insulation of their house since it affects their comfort and monthly utility bills. At the heart of insulation effectiveness lies the concept of R value. This section explores the R-value, its importance in the insulation world, and how it fundamentally works.

Understanding R-value

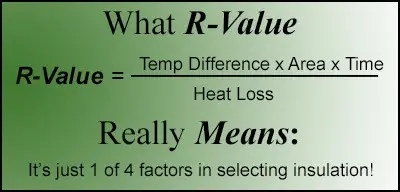

R-value measures thermal resistance, indicating how well a material can resist heat flow. Basically, materials with high thermal resistance have better insulation. This metric is essential for improving a building’s energy efficiency, whether in new construction or retrofitting existing structures.

The Significance of R-value in Insulation

The primary function of insulation is to maintain a comfortable indoor environment by slowing heat transfer. During winter, insulation helps keep warm air inside; in summer, it keeps the heat out. Thermal resistance plays a pivotal role in this process.

A material with a high R-value will be more effective in preventing heat transfer than one with a lower R-value. This effectiveness is not just a matter of comfort but has significant implications for energy consumption and costs.

Understanding R-value is fundamental for anyone involved in building construction or renovation. It provides a clear metric for judging the effectiveness of insulation materials. Selecting the right thermal resistance value for a specific application can significantly enhance a building’s energy efficiency, reduce energy costs, and contribute to a more sustainable future.

Measuring R-Value

Understanding how the R-value is measured is crucial to ensuring effective insulation in any building. This section delves into the processes and factors involved in measuring thermal resistance, highlighting its importance in selecting the right insulation materials.

The Process of Measuring R-value

Measuring the thermal resistance involves assessing a material’s resistance to heat flow. This is done under controlled conditions to ensure accuracy. The process typically includes:

- Setting Controlled Conditions: The material is placed in an environment with regulated temperature and humidity.

- Applying Heat Flow: A steady heat flow is introduced across the material.

- Calculating Temperature Difference: The temperature difference across the material is measured.

- Determining R-value: This value is calculated based on the temperature difference, the heat flow rate, and the material’s thickness.

Factors Affecting R-value Measurements

Several factors can influence the thermal resistance of insulation materials:

- Material Type: Different materials have inherent properties. For example, foam insulations generally have higher thermal resistance than fibrous insulations like fiberglass.

- Thickness: The thickness of the material is directly proportional to its thermal resistance. Increasing thickness typically leads to a higher R-value.

- Density: Denser materials can have different R-values compared to less dense materials of the same type.

- Age and Condition: Materials may settle or degrade over time, affecting their thermal resistance.

- Environmental Factors: Humidity and temperature can also impact the thermal resistance of a material.

Importance of Accurate R-value Measurement

Accurate thermal resistance measurement is crucial for several reasons:

- Energy Efficiency: A correct R-value ensures that insulation performs as expected, maintaining energy efficiency.

- Cost-Effectiveness: Knowing the accurate thermal resistance helps in selecting the most cost-effective insulation material.

- Compliance with Regulations: Accurate R-value measurements ensure compliance with building codes and regulations, which often specify minimum thermal resistance requirements.

Challenges in Measuring R-value

Despite its importance, measuring its thermal resistance comes with challenges:

- Variability in Conditions: Changes in environmental conditions can lead to variations in R-value measurements.

- Material Inconsistencies: Variations in the manufacturing process can result in differences in R-value even within the same material type.

- Long-Term Performance: Predicting how a material’s thermal resistance will change over time can be challenging.

Measuring the thermal resistance is a critical step in selecting and applying insulation materials. Understanding the process and factors involved is key for builders, architects, and homeowners alike.

Accurate measurement ensures that buildings are insulated effectively, enhancing energy efficiency and reducing costs. As we move towards more sustainable building practices, the role of thermal resistance in measuring and achieving energy efficiency becomes even more significant.

R-Value in Different Materials

The effectiveness of insulation in any building heavily relies on the thermal resistance of the materials used. This section explores how the R-value varies across different insulation materials. We shed light on how each material’s unique properties contribute to its insulating capabilities. Understanding these variations is key to selecting the right insulation for specific applications and climates.

Fiberglass Insulation

Fiberglass is one of the most common insulation materials used in buildings. Made from fine glass fibers, it’s known for its fire resistance and sound insulation properties. F

Manufacturing fiberglass involves melting glass and spinning it into fibers. These fibers are then woven to create insulation products like batts, rolls, and loose-fill insulation.

Characteristics of Fiberglass

Fiberglass insulation’s effectiveness is partly due to its structure, which traps air pockets, slowing the spread of heat and cold. This material is lightweight, easy to install, and fits in various spaces, making it a popular choice for residential and commercial buildings.

R-Value Range

The thermal resistance of fiberglass insulation typically ranges from R-2.9 to R-3.8 per inch of thickness. High-density fiberglass batts can have a value as high as R-4.3 per inch. The performance of fiberglass insulation is influenced by how well it’s installed; gaps or compression can significantly reduce its effective thermal resistance.

Applications

Fiberglass is versatile and suitable for insulating walls, attics, and floors. It’s available in batts and rolls for easy installation between studs and joists and in loose-fill form for blowing into hard-to-reach areas.

Cellulose Insulation

Cellulose insulation, another widely used material, is made from recycled paper products, primarily newspaper, treated with fire retardants. This eco-friendly option has gained popularity due to its sustainability and energy efficiency.

Properties of Cellulose

Cellulose insulation is known for its excellent thermal and sound insulation properties. It has a higher density than fiberglass, allowing it to create a better air barrier. Cellulose is also known for its ability to fit snugly in irregular spaces and around obstructions, providing a more airtight seal.

R-Value Range

The R-value of cellulose insulation typically ranges from R-3.1 to R-3.8 per inch, making it comparable to fiberglass. One of the benefits of cellulose is its ability to maintain its value during extreme temperatures, unlike other materials whose thermal resistance can decrease in very hot or cold conditions.

Applications

Cellulose is commonly used in attics, walls, and floors. It can be installed using a loose-fill technique, blown into spaces, or applied as a dense-pack or wet spray for new construction or retrofitting existing structures.

Foam Board Insulation

Foam board insulation, known for its high R-value per inch, is a rigid insulation panel. It’s made from polystyrene, polyisocyanurate (polyiso), and polyurethane. These boards are effective for insulating everything from roofs to foundations.

Characteristics of Foam Board

Foam board insulation stands out for its excellent thermal resistance and moisture barrier properties. Its rigid form allows it to be used in various applications where space is limited. Foam boards are known for their durability and strength, making them suitable for use in exterior insulation systems and interior applications.

R-Value Range

The R-value of foam board insulation varies based on the material. For example, extruded polystyrene (XPS) typically has a value of about R-5 per inch, while polyisocyanurate has a higher value, usually around R-6 to R-7 per inch. This makes foam boards more efficient for achieving high insulation levels with less thickness than other materials.

Applications

Foam boards are versatile and can be used in a variety of settings. They are often applied to basement walls beneath concrete floor slabs, exterior walls under siding, and flat roofs. Their ability to resist moisture makes them particularly useful in areas prone to dampness.

Spray Foam Insulation

Spray foam insulation is a unique material that expands and hardens upon application. It’s made from liquid polyurethane and is applied using a spray gun. This insulation effectively seals gaps, cracks, and voids, making it an excellent choice for irregular or hard-to-reach spaces.

Understanding Spray Foam

There are two main types of spray foam insulation: open-cell and closed-cell. Open-cell foam is softer and more flexible, with a lower thermal resistance, while closed-cell foam is denser, more rigid, and higher R-value. Spray foam not only insulates but also adds structural strength to a building.

R-Value Variations

The R-value of spray foam insulation varies between the types. Open-cell foam typically has a value of about R-3.5 per inch, while closed-cell foam can range from R-6 to R-7 per inch. Closed-cell foam’s higher value makes it particularly effective in extreme weather conditions.

Applications

Spray foam insulation is used in various applications, including walls, roofs, attics, and crawl spaces. Its ability to conform to any shape and create an airtight seal makes it ideal for insulating irregular shapes and retrofitting older buildings.

Mineral Wool Insulation

Mineral wool insulation, also known as rock or slag wool insulation, is made from natural rock or industrial waste. This material is known for its fire resistance and soundproofing abilities, making it a popular choice in residential and commercial constructions.

Properties of Mineral Wool

Mineral wool stands out for its ability to withstand high temperatures and provide excellent sound insulation. It’s also moisture-resistant and does not support mold growth. Its fibrous structure enables it to trap air, slowing heat transfer. Mineral wool is also recognized for its durability and environmental sustainability, as it often contains a high percentage of recycled materials.

R-Value Range

The R-value of mineral wool insulation typically ranges from R-3.0 to R-3.3 per inch. While this is slightly lower than some foam insulations, its fire-resistant and soundproofing qualities often make it the material of choice for specific applications.

Applications

Mineral wool is versatile and can be used in various building parts, including walls, roofs, and floors. It’s particularly effective for fire-stopping applications due to its high melting point. Mineral wool comes in batts, rolls, or loose-fill, providing flexibility in installation for different construction needs.

Polystyrene Insulation

Polystyrene insulation, a type of foam board insulation, is made from a synthetic aromatic hydrocarbon polymer. It is available in two main forms: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS).

Characteristics of Polystyrene

Polystyrene insulation is known for its excellent thermal insulation properties and moisture resistance. EPS is typically the less expensive option with lower density and R-value. On the other hand, XPS offers a higher thermal resistance and greater moisture resistance but at a higher cost.

R-Value Range

For EPS, the R-value ranges from about R-3.6 to R-4.0 per inch, while XPS offers a value between R-4.5 to R-5.0 per inch. The higher value of XPS makes it a more efficient insulator, though the choice between EPS and XPS often depends on budget and specific application requirements.

Applications

Polystyrene insulation is commonly used in various applications, including wall insulation, roof insulation, and below-grade applications like foundations and basements. Its moisture resistance makes it particularly suitable for areas susceptible to dampness.

Reflective Insulation and Radiant Barriers

Reflective insulation and radiant barriers are unique in the world of insulation materials. Unlike traditional insulating materials that resist conductive and convective heat flow, reflective insulation reflects heat away, reducing the radiant heat transfer from hot surfaces.

The Concept Behind Reflective Insulation

Reflective insulation consists of materials like aluminum foil faced with paper, film, or polyethylene bubbles. These materials reflect radiant heat, effectively reducing heat gain in summer and heat loss in winter. This type of insulation is particularly effective in hot climates where radiant heat is a significant concern.

R-Value in Radiant Barriers

The R-value for reflective insulation is not measured like for other insulation materials because its effectiveness largely depends on installation, location, and the heat flow direction. While it doesn’t have a high R-value in the traditional sense, its ability to reflect heat can significantly improve a building’s overall energy efficiency.

Applications

Radiant barriers and reflective insulation are typically used in attics, especially in hot climates. They can be installed under roofs to reduce sun heat, helping keep attics and the living spaces below cooler.

Natural and Sustainable Insulation Materials

Recently, there has been a growing interest in natural and sustainable insulation materials. These materials not only provide effective insulation but also offer environmental benefits.

Overview of Eco-Friendly Options

Natural insulation materials include sheep’s wool, cotton, hemp, and cellulose (recycled paper). These materials are renewable, biodegradable, and often have lower embodied energy than traditional insulation materials.

R-Value Considerations

The R-values for these natural materials can vary. For instance, sheep’s wool typically has an R-value similar to fiberglass, around R-3.5 per inch. Cellulose, which is denser, can have a slightly higher R-value. The effectiveness of these materials also depends on factors like density and how they are installed.

Applications

Natural insulation suits various applications, including walls, roofs, and floors. They are particularly appealing to those seeking to reduce the environmental impact of their buildings, offering a sustainable alternative to traditional insulation materials.

R-Value and Building Regulations

Building regulations ensure that structures are safe, energy-efficient, and environmentally friendly. One of the key components in these regulations is the requirement for insulation R-value. Adhering to these standards is not just a matter of compliance; it also impacts buildings’ energy efficiency and long-term sustainability.

Importance of R-Value in Building Codes

Building codes specify minimum R-value requirements for different building parts, such as walls, roofs, and floors. These requirements are based on the need for efficient thermal insulation, ultimately leading to reduced energy consumption and lower utility bills. Compliance with these codes is crucial for passing building inspections and for the overall success of the construction project.

Regional Variations in R-Value Requirements

R-value requirements in building codes vary significantly across different regions and climates. Higher R-values are typically required in colder areas to ensure adequate insulation against the cold. Conversely, the focus might be more on resisting heat gain in warmer climates, and the R-value requirements may be lower. Understanding these regional differences is crucial for builders and architects.

Impact on Construction and Renovation

The R-value requirements impact both new construction and renovation projects. Builders must select insulation materials that meet or exceed the specified R-values in the building codes. This often involves carefully balancing cost, effectiveness, and material properties. In renovations, upgrading insulation to meet current R-value standards can be challenging, especially in older buildings with limited space for insulation.

Challenges in Compliance

Complying with R-value requirements can present challenges, particularly in complex building designs or when using unconventional materials. Additionally, the evolving nature of building codes, which may become more stringent over time, requires builders and designers to stay informed and adapt their practices accordingly.

Improving Home Energy Efficiency with R-Value

The R-value of insulation materials directly impacts a home’s thermal performance. Homeowners can significantly improve their energy efficiency by understanding and optimizing R-value. This leads to cost savings and a more sustainable and comfortable living environment.

Assessing Current Insulation

The first step in improving energy efficiency is to assess the existing insulation. This involves checking the current insulation’s type, condition, and R-value in various home parts, such as the attic, walls, and floors.

Upgrading Insulation

If the current insulation is inadequate, upgrading to materials with a higher R-value can be a game-changer. This might include adding more insulation layers or replacing old materials with new, more efficient ones.

Addressing Air Leaks

Improving insulation isn’t just about R-value; it’s also essential to seal air leaks. Gaps around windows, doors, and other openings can undermine insulation’s effectiveness. Sealing these leaks enhances the overall insulation performance.

Consider investing in sealants, to create an effective enclosure that prevents heat from escaping. Its high-density foam has a uniform cell structure that makes it highly flexible to be resistant to cracks caused by structural movement.

Insulation and Ventilation Balance

While improving insulation, it’s crucial to maintain proper ventilation. This balance ensures that while the home is well insulated, it has adequate air exchange to prevent moisture buildup and maintain air quality.

Energy-Efficient Windows and Doors

Windows and doors can be significant sources of heat loss. Upgrading to energy-efficient models with higher R-values can further enhance home insulation.

Tailoring Insulation to Climate

The optimal R-value for insulation depends on the local climate. Higher R-values are generally necessary in colder regions, whereas moderate R-values may suffice in milder climates. Tailoring insulation to the specific climate is key to maximizing energy efficiency.

Innovative Insulation Technologies

Exploring new insulation technologies can offer additional ways to improve energy efficiency. Materials like vacuum-insulated panels and phase-changing materials are examples of innovative solutions that might offer superior R-values and performance.

Regular Maintenance and Inspections

Regular maintenance and inspections can ensure insulation remains effective over time. This can involve checking for dampness, settling, or damage to insulation materials.

Impact on Energy Costs and Environmental Footprint

Improving home energy efficiency through better insulation has a direct impact on reducing energy costs. It also lowers the home’s environmental footprint by reducing energy consumption and greenhouse gas emissions.

FAQ on R-Value Home Insulation

Can R-value degrade over time, and how can it be maintained?

The R-value of insulation can degrade over time due to factors like moisture, settling, or damage. Regular inspections and maintenance, such as checking for water damage or ensuring the insulation hasn’t compressed, can help maintain its effectiveness.

Are there any health concerns associated with insulation materials?

Certain insulation materials, like fiberglass, can pose health risks if not handled properly. It’s important to follow safety guidelines, such as wearing protective gear during installation. Newer materials are being developed with a focus on reducing health risks.

How does insulation contribute to soundproofing?

Insulation materials can absorb sound, reducing noise transfer between rooms and from outside. Materials like mineral wool are particularly effective for soundproofing due to their dense fibrous structure.

Can insulation improve indoor air quality?

Proper insulation can improve indoor air quality by reducing drafts and preventing the infiltration of outdoor pollutants. However, it’s important to balance insulation with adequate ventilation to prevent moisture buildup.

Are there insulation options for homes in extremely humid climates?

In humid climates, choosing insulation that resists moisture is crucial, such as closed-cell foam insulation. Proper installation and a good vapor barrier are essential to prevent mold growth and moisture damage.

How does the R-value requirement differ for commercial and residential homes?

Commercial buildings often have different R-value requirements due to larger open spaces, higher ceilings, and different usage patterns. Building codes typically have specific R-value guidelines for commercial structures.

What are the cost implications of choosing high R-value insulation?

Initially, high R-value insulation can be more expensive. However, it can lead to significant energy savings over time, making it cost-effective in the long run. It’s important to consider upfront costs and long-term savings when selecting insulation.

Is it possible to have too much insulation in a home?

Excessive insulation can lead to problems like reduced indoor air quality and moisture issues. Following recommended R-value guidelines and ensuring proper ventilation is important to avoid these issues.

How does insulation contribute to a building’s fire safety?

Some insulation materials, like mineral wool, are non-combustible and can enhance a building’s fire safety. However, other types may require additional fireproofing measures. It’s important to consider fire safety when choosing insulation materials.

Can insulation be recycled or reused?

Some insulation materials, like certain foams and cellulose, can be recycled or reused. The recyclability of insulation is increasingly becoming a consideration in sustainable building practices.

Conclusion

Understanding the R-value of insulation materials is crucial for anyone looking to improve the energy efficiency of their home or building. When we talk about R-value, we talk about comfort, savings, and caring for our planet. This guide helps homeowners and builders make wise choices in insulation, ensuring our spaces are up to code cozy, cost-effective, and kind to the environment. Understanding R-value is about creating spaces that feel good, are economically smart, and are environmentally sound.