Recommended Parts

*Grommets or bushings for sound holes

*Stain or varnish – a plain sanded neck is great but a stain or varnish can really elevate your work and bring out the natural beauty of the hardwood in your neck. Aerosolised beeswax furniture polish is a brilliant way to finish the wood with very little work.

Tools

Having access to tools like a drill press, band saw, router and orbital sander will definitely make the process of constructing a cigar box guitar a lot faster and easier, but in reality, you only need a couple of hand tools to get the project underway.

Here’s what you’ll definitely need

*Coping Saw/Keyhole Saw – if you don’t already have one you can usually pick up a coping saw from any hardware store, hobby store, or junk shop for under $10

*Screwdrivers – the exact sizing will depend on the screws needed for affixing the tailpiece and machine heads.

*A Drill/Drill bits – hardwoods require the drilling of guide holes for screws so the wood doesn’t split. An electric drill will make the job a lot easier but a hand drill and some patience will definitely suffice. A standard set of drill bits should have everything you need, from 1/16” for drilling guide holes through to 1/2” bits for making sound holes.

*Sandpaper – you don’t need to get your neck baby smooth but the last thing you want is a splinter from the neck of your guitar. Various grades of sandpaper are a must.

*Wood File – a wood file isn’t entirely necessary but there’s nothing quite like one for enlarging holes and taking off big burrs.

Recommended tools

*Sharp Chisels

*Rats Tail File

Shaping the Neck

In the old money, you should cut your neck to be 34” long (that’s a little over 86cm), but any length between 85 and 90cm is just about perfect. Keep any offcuts as they will definitely come in handy later for measurement purposes.

Once you’ve cut your neck to the desired length you need to thin the headstock so it’s thin enough that the machine heads have enough room to function. The depth of the recess required will really depend on the specific machine heads you have bought, but thinning the neck to about 1.25-1.5cm should suffice for most makes. For a three string design, the length of the head stock should be around 11-12cm – this will give you enough space to position the tuners adequately and stop the strings from crowding.

Once you’ve marked out the cut lines use your saw to remove the cut-out. How easy this cut will be really depends on the quality of your saw and the density and dryness of your wood. If you’re having trouble cutting you can try using your saw to cut tightly spaced guide lines down to the desired depth and then use a sharp chisel to remove the wood. Using this method does mean that you will have to put in some time with a rasp or file and sandpaper to get it smooth, but for hard woods like Jarrah (as used in this build) it makes matters a whole lot easier.

Body Cut-out

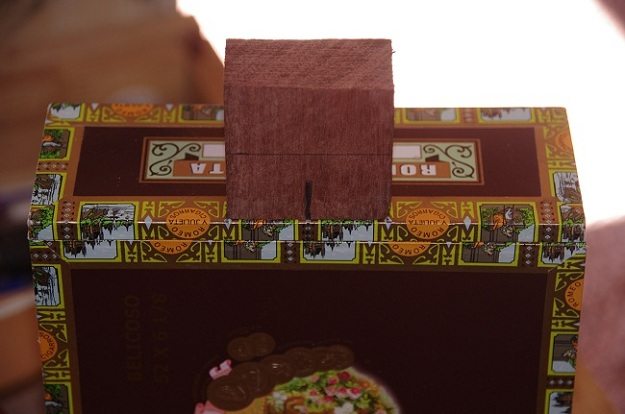

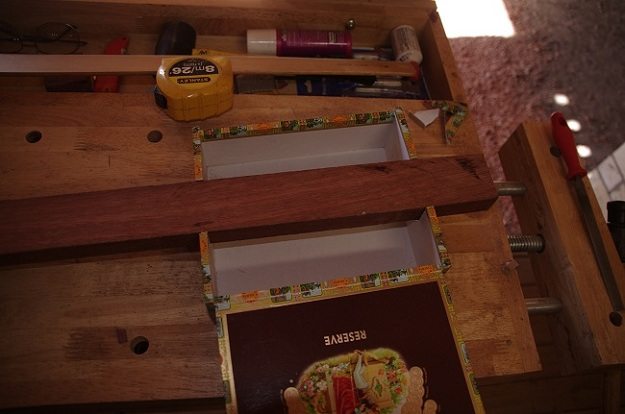

Once you have your headstock cut and smoothed it’s time to work out exactly where your neck will fit through your cigar box body. Measure the centre point of each side of your box and mark it with a pencil. Here’s where the cut off length of wood comes into play. Mark the centre part of one of your cut-off lengths and align with the mark on your box. Tracing around the wood will give you a good guide for where to cut.

Make sure to cut within the lines. Don’t worry if the holes are too small to begin with – you can always enlarge your cuts with a file. The neck should fit snugly into the box and sit flush with the top edge. This design of guitar is only held together by friction and the tension of the strings, so care and precise cutting are important.

Two things you should keep in mind before making the cuts – make sure the neck will extend from the correct side and be sure that the artwork on the cigar bow will be the right way up when the build is finished. Making sure that the art is oriented correctly will not only make your guitar look better, it will also ensure that the lid will hinge from the top edge, making the guitar sturdier in the long run.

Continued page 3…