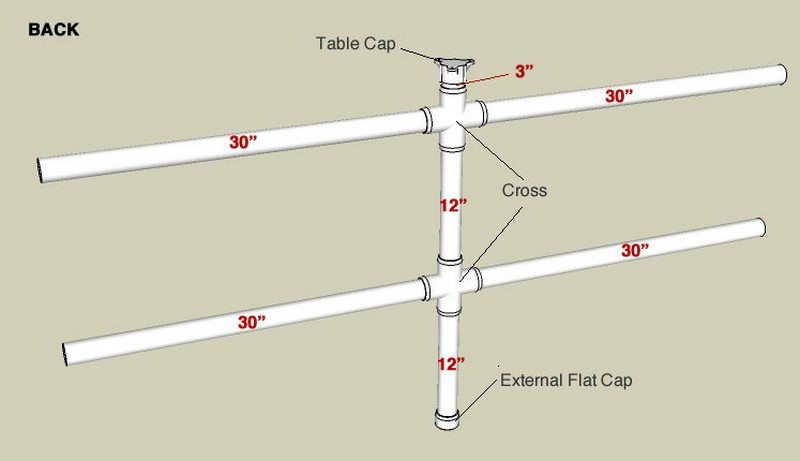

Now its time to build the ‘BACK’ of the PVC table, which is a fairly simple. For this step, you will need a Table Cap, an External Cap and two Crosses, both which should not have not yet been used. Assemble them, along with the long pieces of 30” pipe to make something that looks like it belongs on the top of a telephone pole.

When assembling the ‘center stack’ with PVC cement, lay this flat on the floor so that everything is flat and your pipe is all parallel.

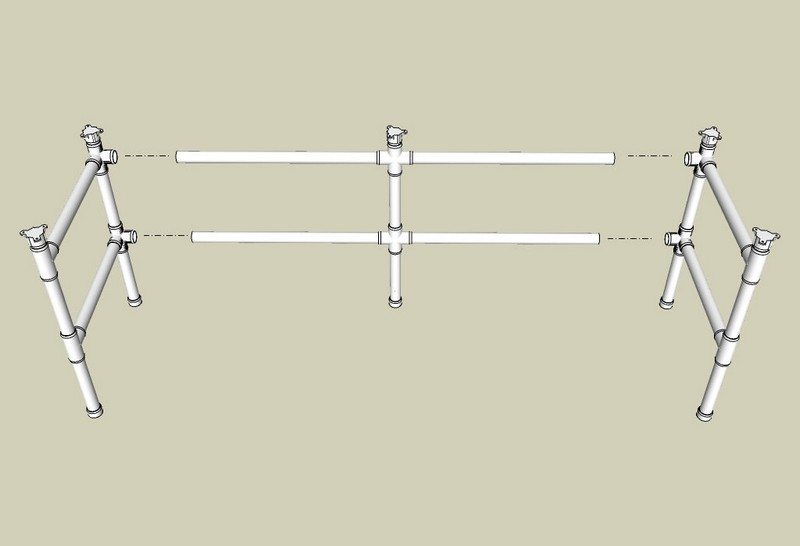

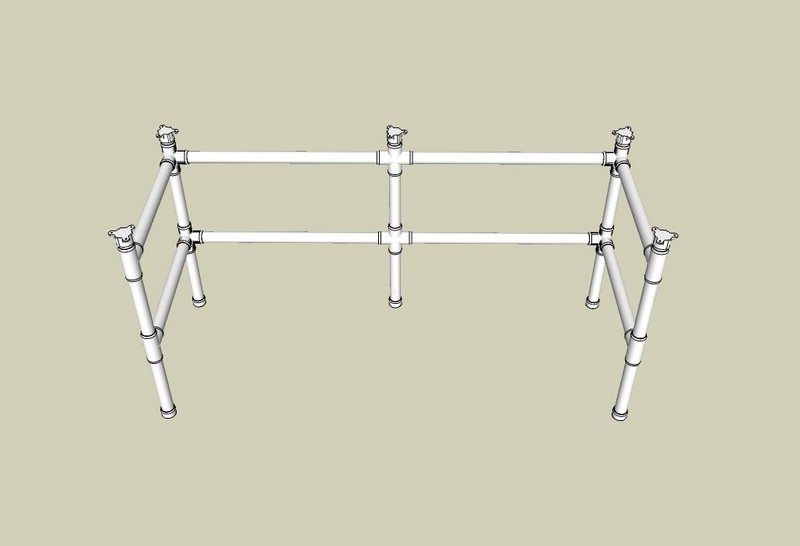

Now its time to bring everything (PVC-related) together.

Insert the ends of the pipes from the BACK into each of the SIDE 1 and SIDE 2 elements of your PVC table to end up with something shown in the diagram. Again, I recommend a dry fit to make sure everything lines up before applying PVC cement.

Once you a comfy with the dry fit, pull them apart and apply PVC cement into the fittings on SIDE 1, and insert the BACK pipes into the 4-Way Tees on SIDE 1. Quickly make sure everything is sitting a right angles. Press together and wait 30 seconds.

Next, apply PVC cement into the fittings on SIDE 2 of your PVC table, and insert the BACK pipes into the 4-Way Tees on SIDE 2. Quickly make sure everything is sitting a right angles. Again, press together and wait 30 seconds.

You should now have a completed frame for your PVC table! Almost Done!

The Trouble with Hollow-Core Doors:

Hollow-core doors are constructed of an outer frame and various slats that run (when stood upright) along the horizontal plane of the door. The remainder of the area between these slats is either filled with cardboard (seriously), foam or just plain nothing.

Since we can’t see where those slats are for your PVC table, I found that it is a hit-or-miss scenario as to where our table caps will end up attaching to the door, be it a slat or a fluffy piece of cardboard. Where it is cardboard we want to use a drywall insert, to attach the cap to the wood or wall of the door instead. Here is how we do it:

- Lay the hollow-core door on the floor, with the side you want to be the top, facing the floor, then flip the PVC structure over and place it, upside down onto the door, with the table caps against the door.

- Center the whole structure by eyeballing the placement of the PVC pipe segments and their relation to the edges of the door, then using a pencil or Sharpie marker, mark where the holes in the Table Caps meet the door.

- Remove the PVC structure and place it to the side. With a drill or electric screwdriver, insert a screw into each of the marked points you just made on the door.

- If it goes in easily, you have hit a hollow point in the door. Remove the screw and insert a drywall screw insert into these holes (if you need to, make the hole bigger with a drill bit).

- If it goes in and catches the threads, you have hit a slat, and the hole is good as it is. No drywall screw insert is needed. Remove the screw.

Once you have determined where you need/don’t need inserts of your PVC table, make sure all of your ‘test screws’ have been removed and replace the PVC structure back onto the table top and align the table caps with the holes that have been predrilled.

NOTE: All of this can be avoided if you use a solid-core door for your PVC table. I am $25 under budget on each table for not doing so, but alas, I am a cheap, cheap man.

Finally, insert the screws into the table caps and into the door/screw inserts. You now have a fully-completed, upside down table.

Finally, flip the table over and you should have (if I have explained myself correctly) a fully functional, huge, sturdy table.

You can finish the table with paint, or a nice stain if so desired. We chose to keep ours ‘natural’, however water stains show up like mad on the thin wood, so we recommend a light waterproofing stain or paint.

Customizing

As with any project involving PVC and found parts, you can make any adjustments to suit your particular needs. Doors come in shorter lengths, so you can easily change the length of the 30″ pipe segments to 24″ or 28″ to accommodate shorter doors. You can also increase the height of the table by increasing the 3″ lengths of pipe under the table caps, to make a table that is more suited for standing or counter height.

Thanks to trevormates for this great project!

Contents

PVC Table Designs for Specific Uses

PVC tables offer a versatile and cost-effective solution for creating tailored workspaces for a variety of specific uses. Whether you need a sturdy desk for your home office, a spacious surface for arts and crafts, or a durable table for outdoor gatherings, PVC’s adaptability allows for customization to meet your exact requirements.

In this section, we explore PVC table designs optimized for different activities, showcasing the practicality and flexibility of PVC as a material for DIY projects.

Home Office PVC Table

A PVC table designed for a home office can be customized to accommodate computers, peripherals, and ample workspace for paperwork. By incorporating wider and longer PVC pipes, you can create a large surface area with plenty of room for monitors, keyboards, and office supplies.

Consider adding a second tier by using PVC pipes and fittings to hold monitors at eye level, improving ergonomics and freeing up valuable desk space.

Arts and Crafts PVC Table

For those who love crafting, a PVC table can be transformed into an ideal workspace with storage solutions for tools and materials. Adding side extensions with PVC fittings can create additional space for sewing machines or cutting mats.

Incorporate PVC pipe segments vertically beneath the table to hold rolls of paper or fabric. The lightweight nature of a PVC table makes it easy to move, allowing you to adjust your crafting area as needed.

Gaming PVC Table

A gaming PVC table requires a sturdy structure to support multiple monitors, gaming consoles, and heavy peripherals. Utilize thicker PVC pipes for enhanced stability and consider adding a cross-brace design for extra support.

A custom PVC table can also feature built-in cable management solutions, such as PVC conduits under the table, to keep wires organized and out of sight. Adjustable height is another beneficial feature, enabling gamers to switch between sitting and standing positions for comfort during long sessions.

Outdoor PVC Table

PVC’s resistance to water and rust makes it an excellent choice for outdoor tables. A simple PVC table can be designed with a removable top for easy cleaning and storage.

For outdoor dining or activities, incorporate a hole in the center of the tabletop to accommodate an umbrella, providing shade and protection from the elements. UV-resistant PVC pipes ensure the table remains durable and maintains its appearance even when exposed to sunlight.

Kid’s Play PVC Table

Create a fun and safe play area for children with a PVC table designed specifically for their needs. A smaller, kid-sized PVC table can be perfect for drawing, building with blocks, or playing with toys.

Incorporating storage options such as baskets or bins attached to the PVC frame helps keep play areas tidy. Use PVC end caps to cover exposed pipe ends for added safety, preventing scratches and injuries.

Adjustable Height Craft Table

Craft enthusiasts who engage in various activities can benefit from an adjustable-height PVC table. By incorporating telescopic PVC legs that adjust with set screws or pins, crafters can alter the table height based on the task at hand, whether sitting or standing. This flexibility is ideal for projects ranging from painting to model building, providing ergonomic comfort and enhancing productivity.

Portable Picnic PVC Table

For those who enjoy the outdoors, a portable picnic PVC table is a lightweight and easily transportable solution. Design this table with detachable legs and a foldable top, enabling compact storage and mobility.

Utilize durable, weather-resistant PVC materials to ensure the table withstands elements like sun and rain. This table design is perfect for camping trips, beach outings, and backyard barbecues.

Gardening Workstation PVC Table

Gardeners will appreciate a PVC table designed as a gardening workstation, complete with integrated features for potting and planting. Add a built-in sink or basin for soil mixing and a lower shelf made from PVC mesh for storing gardening tools and pots.

The table’s surface can include a recessed area to keep soil contained, making cleanup easier. This PVC gardening table combines functionality with the durability needed for outdoor use.

Minimalist Modern PVC Desk

For those who taste modern aesthetics, a minimalist PVC desk design offers clean lines and a sleek profile. Clear PVC pipes and fittings create an almost invisible frame, topped with a glass or high-gloss acrylic surface. This design emphasizes the modern minimalist trend and creates the illusion of more space, making it ideal for small home offices or apartments.

Multi-Level Plant Stand PVC Table

A multi-level PVC table designed as a plant stand allows for an attractive display of indoor plants, herbs, or flowers. Construct levels at varying heights by using different lengths of PVC pipe, creating a tiered effect that showcases each plant beautifully.

This design can be adapted to fit any indoor space, offering a functional and decorative element that brings a touch of nature indoors.

Mobile Bar and Beverage PVC Cart

Entertaining enthusiasts can build a mobile bar and beverage cart from PVC, featuring multiple tiers for storing drinks, glassware, and accessories. Incorporate casters at the base for easy movement, making it perfect for social gatherings, parties, or as a permanent fixture in a home entertainment area. The cart’s top can serve as a mixing and serving station, with additional storage below for bottles and bar tools.

Incorporating these PVC table designs into your home or outdoor space saves money and allows for a high degree of customization. Whether you’re assembling a dedicated workspace or creating a fun area for kids, PVC tables offer a practical, durable, and adaptable solution that can be tailored to suit any specific use.

Safety Precautions and Maintenance Tips

Creating and using a PVC table involves straightforward construction and easy maintenance, making it an appealing choice for various projects. However, it’s crucial to follow certain safety precautions during assembly and to adhere to maintenance tips to ensure the table’s longevity and safe use.

This section covers essential safety guidelines and maintenance advice for PVC tables, ensuring they remain durable and secure for all types of activities.

Safety Precautions

- Material Handling: When cutting PVC pipes for your table, always wear protective eyewear to shield against flying debris. Gloves can prevent cuts and scrapes during handling and assembly. Ensure your workspace is well-ventilated, especially with PVC cement, as it emits strong fumes that can be harmful if inhaled in confined spaces.

- Structural Stability: To guarantee the stability of your PVC table, ensure all connections between pipes and fittings are secure. If using PVC cement, apply it carefully to avoid weak bonds. For tables bearing significant weight, consider reinforcing joints with screws or additional support structures to prevent collapse.

- Weight Distribution: Be mindful of the PVC table’s weight capacity. Distribute weight evenly across the tabletop to prevent undue stress on any single point, which could lead to structural failure. Avoid placing overly heavy items on the table, especially if the design is meant for lighter use, such as a crafting or display table.

Maintenance Tips

- Regular Cleaning: PVC tables are easy to clean due to their smooth surfaces. Wipe down your table regularly with a mild detergent and water to keep it looking new. For tougher stains, a solution of vinegar and water can be effective. Avoid abrasive cleaners or pads, as they can scratch the surface.

- Inspecting Joints and Connections: Periodically check the joints and connections of your PVC table to ensure they remain tight and secure. If any parts feel loose, tighten them if screws are used, or consider reapplying PVC cement to joints that have weakened over time.

- Avoiding Extreme Temperatures: While PVC resists many environmental factors, extreme temperatures can affect its integrity. Avoid placing your PVC table in direct sunlight for prolonged periods or exposing it to freezing temperatures, making the material brittle and more susceptible to damage.

- Protecting the Surface: To extend the life of your PVC table, consider using a tablecloth or protective mat, especially if the table is used for activities that might scratch or damage the surface. This is particularly useful for crafting or work tables where tools and materials are frequently moved across the tabletop.

By adhering to these safety precautions and maintenance tips, you can enjoy a durable and stable PVC table for years. Regular care and attention ensure that your PVC table remains a reliable and attractive piece of furniture, whether it’s used for work, play, or display.

FAQ on Constructing Your PVC Table

What materials do I need to build a PVC table?

To build a PVC table, you’ll need PVC pipes, furniture grade PVC fittings (such as tees, elbows, and caps), a tabletop material (like a hollow core door or plywood), PVC cement, screws, and tools for cutting and drilling (like a saw and drill).

How do I ensure my PVC table is stable?

Stability can be ensured by using the correct diameter and wall thickness of PVC pipes for the size and expected load of your table. Secure all joints with PVC cement and/or screws, and consider adding cross braces or a lower shelf for additional support.

Can I adjust the height of my PVC table after it’s been built?

Yes, you can adjust the height by replacing the vertical legs with longer or shorter PVC pipes. If you anticipate needing to adjust the height frequently, design your table with adjustable leg extensions that can be secured with set screws.

Is it possible to disassemble and store my PVC table?

Yes, if you design your table with this in mind. Avoid using PVC cement on all joints, or use it selectively, allowing for parts of the table to be disassembled. Screws can also be used to join pieces together, making disassembly easier.

How do I cut PVC pipes accurately for my table?

Measure twice and cut once using a pencil or marker to mark the cutting line. Use a hacksaw, PVC pipe cutter, or a power saw with a fine-tooth blade to make clean and straight cuts. Ensure the cut edges are smooth and free of burrs before assembly.

Conclusion

Building a PVC table offers a versatile and cost-effective solution for creating customized furniture tailored to specific needs and spaces. The process allows for easy assembly and adaptability, ensuring anyone can craft a durable and functional table with minimal tools and materials. With proper safety precautions and maintenance, a PVC table can serve as a reliable and stylish addition to any home or workspace, demonstrating the practicality and creativity of DIY projects.

You can do more with PVC pipes. Check out our PVC birdhouses next!